Produzione di vettori nano-liposomiali incapsulanti ferro altamente biodisponibile con tecnica in continuo

Il progetto “Ferro (II) liposomiale” consiste nella produzione di vettori nano-liposomiali incapsulanti ferro altamente biodisponibile con tecnica in continuo. Dal 2018 Eng4Life possiede il brevetto “Process for preparing nanoliposomes comprising micronutrients and food products comprising said nanoliposomes”.

Il brevetto è consultabile al seguente link.

Il ferro è un micronutriente essenziale che assolve a numerose funzioni.  Di conseguenza, la mancanza di ferro, ovvero l’anemia, nel corpo dell’uomo comporta una serie di effetti indesiderati, quali: stanchezza fisica e mentale, pallore, mal di testa, vertigini, mancanza di respiro, accelerazione del battito cardiaco, perdita di capelli, etc… Secondo l’Organizzazione Mondiale della Sanità (OMS), soffrono di anemia due miliardi di persone al mondo, cioè circa il 30% della popolazione mondiale.

Di conseguenza, la mancanza di ferro, ovvero l’anemia, nel corpo dell’uomo comporta una serie di effetti indesiderati, quali: stanchezza fisica e mentale, pallore, mal di testa, vertigini, mancanza di respiro, accelerazione del battito cardiaco, perdita di capelli, etc… Secondo l’Organizzazione Mondiale della Sanità (OMS), soffrono di anemia due miliardi di persone al mondo, cioè circa il 30% della popolazione mondiale.

In caso di ridotto apporto di ferro, formulazioni a base di ferro liposomiale garantiscono un’elevata biodisponibilità del micronutriente insieme ad un migliore assorbimento dello stesso e ad una bassa tossicità .

I prodotti presenti già sul mercato che contengono ferro trasportato nei liposomi, come ad esempio il pirofosfato ferrico liposomiale (nome commerciale “Sideral”), presentano alcune criticità:

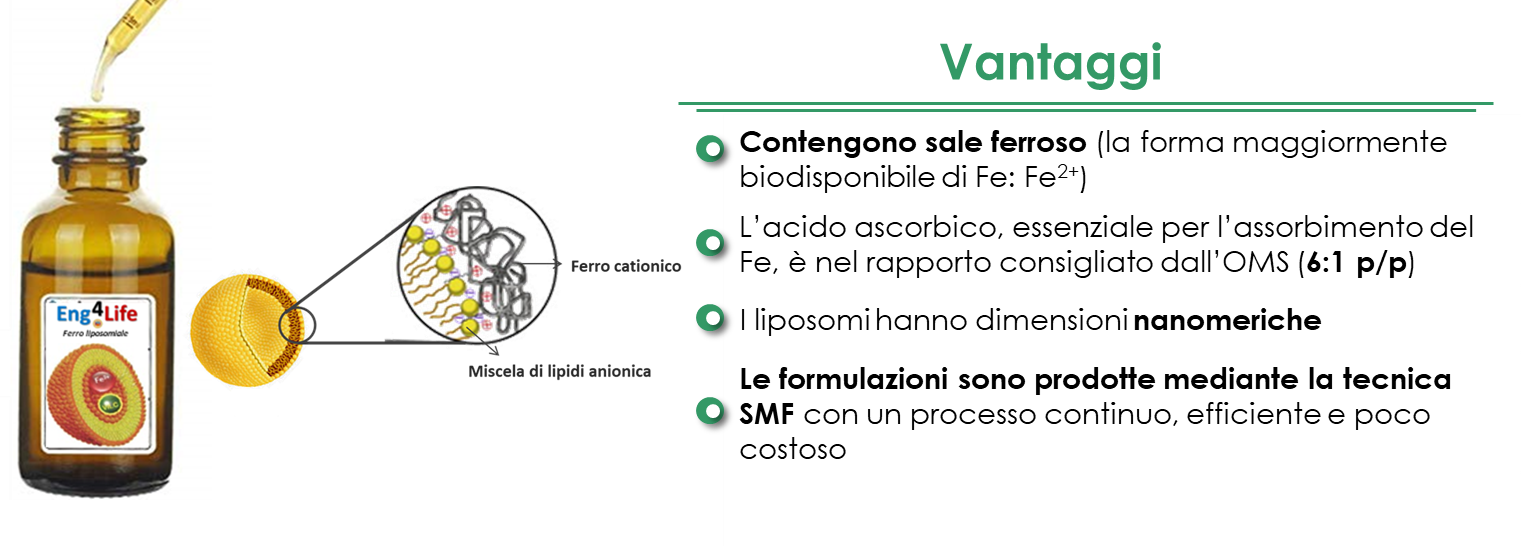

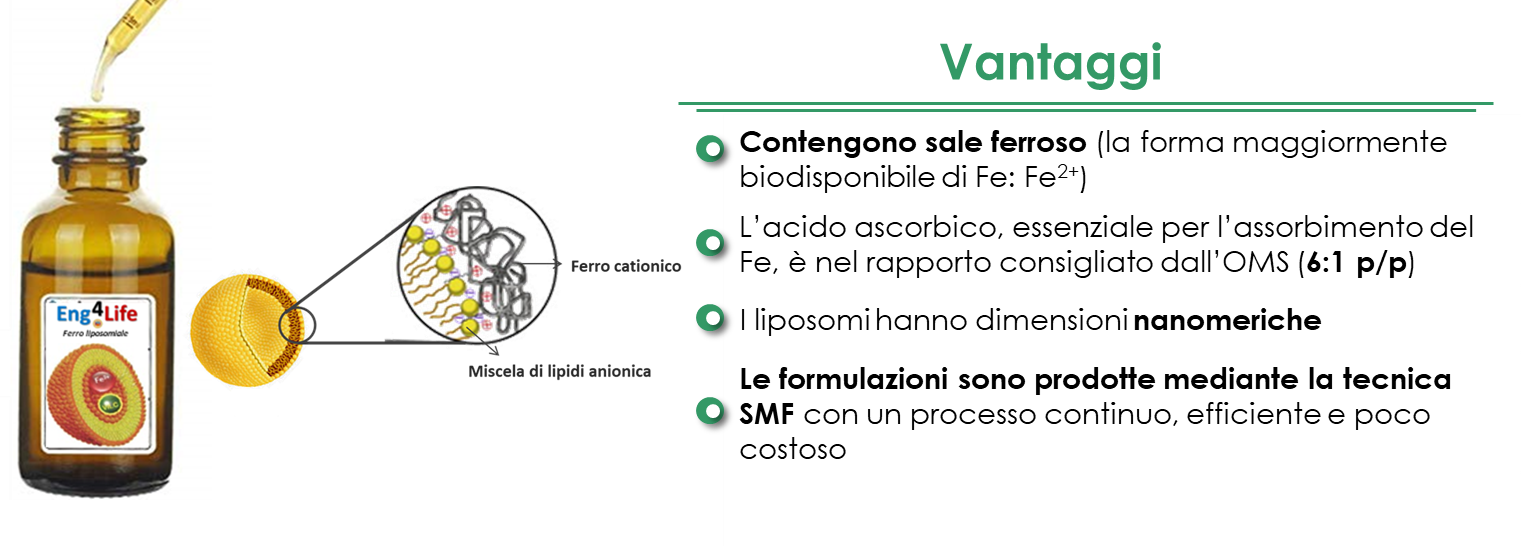

Eng4Life ha ideato e brevettato l’utilizzo nel processo produttivo di vettori nano-liposomiali incapsulanti ferro altamente biodisponibile con tecnica in continuo (SMF-Simil Microfluidica).

Garantendo maggiore stabilità del prodotto e maggiore biodisponibilità.

Di seguito alcune delle pubblicazioni sull’argomento realizzate dai componenti del team di Eng4life.

2020

Bochicchio, Sabrina; Dalmoro, Annalisa; Lamberti, Gaetano; Barba, Anna Angela

Advances in Nanoliposomes Production for Ferrous Sulfate Delivery Journal Article

In: Pharmaceutics, vol. 12, no 5, pp. 445, 2020.

@article{Bochicchio2020b,

title = {Advances in Nanoliposomes Production for Ferrous Sulfate Delivery},

author = {Sabrina Bochicchio and Annalisa Dalmoro and Gaetano Lamberti and Anna Angela Barba},

editor = {MDPI},

url = {https://www.mdpi.com/1999-4923/12/5/445/pdf},

doi = {10.3390/pharmaceutics12050445},

year = {2020},

date = {2020-05-11},

journal = {Pharmaceutics},

volume = {12},

number = {5},

pages = {445},

abstract = {In this study, a continuous bench scale apparatus based on microfluidic fluid dynamic principles was used in the production of ferrous sulfate-nanoliposomes for pharmaceutical/nutraceutical applications, optimizing their formulation with respect to the products already present on the market. After an evaluation of its fluid dynamic nature, the simil-microfluidic (SMF) apparatus was first used to study the effects of the adopted process parameters on vesicles dimensional features by using ultrasonic energy to enhance liposomes homogenization. Subsequently, iron-nanoliposomes were produced at different weight ratios of ferrous sulfate to the total formulation components (0.06, 0.035, 0.02, and 0.01 w/w) achieving, by using the 0.01 w/w, vesicles of about 80 nm, with an encapsulation efficiency higher than 97%, an optimal short- and long-term stability, and an excellent bioavailability in Caco-2 cell line. Moreover, a comparison realized between the SMF method and two more conventional production techniques showed that by using the SMF setup the process time was drastically reduced, and the process yield increased, achieving a massive nanoliposomes production. Finally, duty-cycle sonication was detected to be a scalable technique for vesicles homogenization. },

keywords = {},

pubstate = {published},

tppubtype = {article}

}

In this study, a continuous bench scale apparatus based on microfluidic fluid dynamic principles was used in the production of ferrous sulfate-nanoliposomes for pharmaceutical/nutraceutical applications, optimizing their formulation with respect to the products already present on the market. After an evaluation of its fluid dynamic nature, the simil-microfluidic (SMF) apparatus was first used to study the effects of the adopted process parameters on vesicles dimensional features by using ultrasonic energy to enhance liposomes homogenization. Subsequently, iron-nanoliposomes were produced at different weight ratios of ferrous sulfate to the total formulation components (0.06, 0.035, 0.02, and 0.01 w/w) achieving, by using the 0.01 w/w, vesicles of about 80 nm, with an encapsulation efficiency higher than 97%, an optimal short- and long-term stability, and an excellent bioavailability in Caco-2 cell line. Moreover, a comparison realized between the SMF method and two more conventional production techniques showed that by using the SMF setup the process time was drastically reduced, and the process yield increased, achieving a massive nanoliposomes production. Finally, duty-cycle sonication was detected to be a scalable technique for vesicles homogenization.

2017

Bochicchio, Sabrina; Lamberti, Gaetano; Barba, Anna Angela

Phenomenological and Formulation Aspects in Tailored Nanoliposome Production Book Chapter

In: Liposomes, Chapter 2, IntechOpen, 2017.

@inbook{Bochicchio2017b,

title = {Phenomenological and Formulation Aspects in Tailored Nanoliposome Production},

author = {Sabrina Bochicchio and Gaetano Lamberti and Anna Angela Barba},

url = {https://www.intechopen.com/books/liposomes/phenomenological-and-formulation-aspects-in-tailored-nanoliposome-production},

doi = {10.5772/intechopen.68157},

year = {2017},

date = {2017-10-25},

booktitle = {Liposomes},

publisher = {IntechOpen},

chapter = {2},

abstract = {Liposomes as cell‐mimetic system have attracted wide attention of researchers in various branches of the drug delivery topic as they can be highly functionalized and personalized, thus solving the major drawbacks of bioactive molecules linked to their low stability, limited membrane permeability, short half‐life and low bioavailability. The development of sustainable processes able to produce ad hoc liposomes in a rapid manner through the use of not‐laboured techniques, avoiding drastic conditions, is of great relevance for the industrial sector. In this chapter, two novel liposome production processes, the ultrasound‐assisted thin‐film hydration and the simil‐microfluidic techniques sharing the same size reduction/homogenization preparative step, are presented. The phenomenological aspects involved in vectors constitution through the duty cycle sonication process (bilayer rupture/vesicles formation mechanisms) and through the simil‐microfluidic approach (intubated flows interdiffusion mechanisms) are described. Finally, two applications as case histories involving the use of the developed techniques for relevant classes of active molecule delivery are described. In particular, a pharmaceutical application concerns the encapsulation of short‐interfering RNA (siRNA) molecule, used for gene therapy, inside cationic nanoliposomes, and a nutraceutical application consists in the production of ferrous sulphate anionic liposomal formulations with improved features compared to those already present on the market.},

keywords = {},

pubstate = {published},

tppubtype = {inbook}

}

Liposomes as cell‐mimetic system have attracted wide attention of researchers in various branches of the drug delivery topic as they can be highly functionalized and personalized, thus solving the major drawbacks of bioactive molecules linked to their low stability, limited membrane permeability, short half‐life and low bioavailability. The development of sustainable processes able to produce ad hoc liposomes in a rapid manner through the use of not‐laboured techniques, avoiding drastic conditions, is of great relevance for the industrial sector. In this chapter, two novel liposome production processes, the ultrasound‐assisted thin‐film hydration and the simil‐microfluidic techniques sharing the same size reduction/homogenization preparative step, are presented. The phenomenological aspects involved in vectors constitution through the duty cycle sonication process (bilayer rupture/vesicles formation mechanisms) and through the simil‐microfluidic approach (intubated flows interdiffusion mechanisms) are described. Finally, two applications as case histories involving the use of the developed techniques for relevant classes of active molecule delivery are described. In particular, a pharmaceutical application concerns the encapsulation of short‐interfering RNA (siRNA) molecule, used for gene therapy, inside cationic nanoliposomes, and a nutraceutical application consists in the production of ferrous sulphate anionic liposomal formulations with improved features compared to those already present on the market.

Bochicchio, Sabrina; Dalmoro, Annalisa; Recupido, Federica; Lamberti, Gaetano; Barba, Anna Angela

Nanoliposomes Production by a Protocol Based on a Simil-Microfluidic Approach Journal Article

In: Springer International Publishing AG 2018, no 3-10, 2017, ISBN: 978-3-319-62026-8.

@article{Bochicchio2017,

title = {Nanoliposomes Production by a Protocol Based on a Simil-Microfluidic Approach},

author = {Sabrina Bochicchio and Annalisa Dalmoro and Federica Recupido and Gaetano Lamberti and Anna Angela Barba},

editor = {Stefano Piotto and Federico Rossi and Simona Concilio and Ernesto Reverchon and Giuseppe Cattaneo},

url = {https://link.springer.com/chapter/10.1007/978-3-319-62027-5_1},

doi = {10.1007/978-3-319-62027-5_1},

isbn = {978-3-319-62026-8},

year = {2017},

date = {2017-08-01},

journal = {Springer International Publishing AG 2018},

number = {3-10},

abstract = {In this work a protocol based on the microfluidic principles has been developed and applied to produce nanoliposomes. The protocol basically consists in the realization of a contact between two flows, lipids/ethanol and water solutions, inside a tubular device where interdiffusion phenomena allow the formation of lipid vesicles. Effects of solutions flow rates and lipids concentrations on size and size distribution have been investigated. Moreover, ultrasonic energy was used to enhance homogenization of the hydroalcoholic final solutions and to promote the vesicles size reduction. By this protocol a massive output has been achieved; increasing the ratio between the water volumetric flow rate to the lipids-ethanol volumetric flow rate the liposomes dimension decreases; at equal flow rates, when the lipids concentration increases also the liposomes size has been observed increasing. },

keywords = {},

pubstate = {published},

tppubtype = {article}

}

In this work a protocol based on the microfluidic principles has been developed and applied to produce nanoliposomes. The protocol basically consists in the realization of a contact between two flows, lipids/ethanol and water solutions, inside a tubular device where interdiffusion phenomena allow the formation of lipid vesicles. Effects of solutions flow rates and lipids concentrations on size and size distribution have been investigated. Moreover, ultrasonic energy was used to enhance homogenization of the hydroalcoholic final solutions and to promote the vesicles size reduction. By this protocol a massive output has been achieved; increasing the ratio between the water volumetric flow rate to the lipids-ethanol volumetric flow rate the liposomes dimension decreases; at equal flow rates, when the lipids concentration increases also the liposomes size has been observed increasing.

Di conseguenza, la mancanza di ferro, ovvero l’anemia, nel corpo dell’uomo comporta una serie di effetti indesiderati, quali: stanchezza fisica e mentale, pallore, mal di testa, vertigini, mancanza di respiro, accelerazione del battito cardiaco, perdita di capelli, etc… Secondo l’Organizzazione Mondiale della Sanità (OMS), soffrono di anemia due miliardi di persone al mondo, cioè circa il 30% della popolazione mondiale.

Di conseguenza, la mancanza di ferro, ovvero l’anemia, nel corpo dell’uomo comporta una serie di effetti indesiderati, quali: stanchezza fisica e mentale, pallore, mal di testa, vertigini, mancanza di respiro, accelerazione del battito cardiaco, perdita di capelli, etc… Secondo l’Organizzazione Mondiale della Sanità (OMS), soffrono di anemia due miliardi di persone al mondo, cioè circa il 30% della popolazione mondiale.